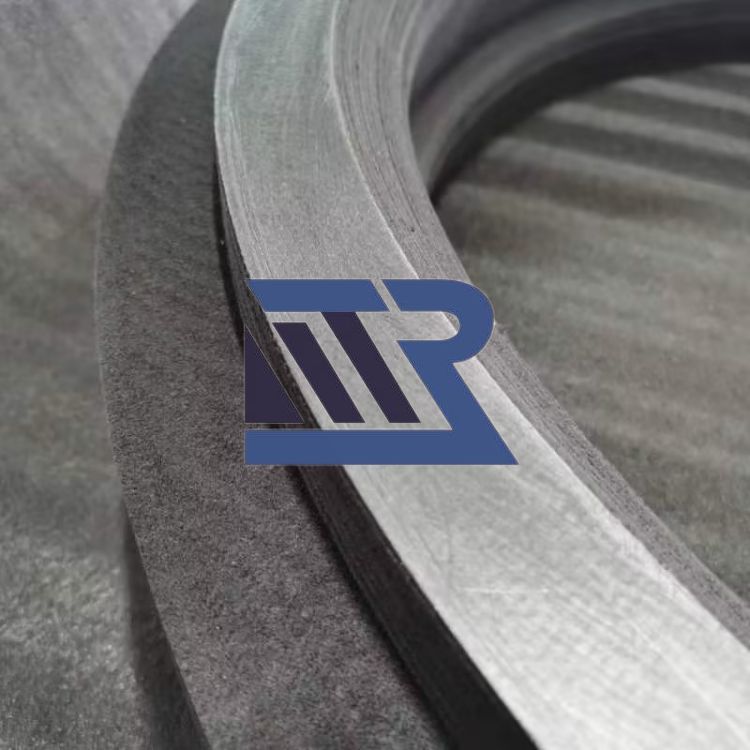

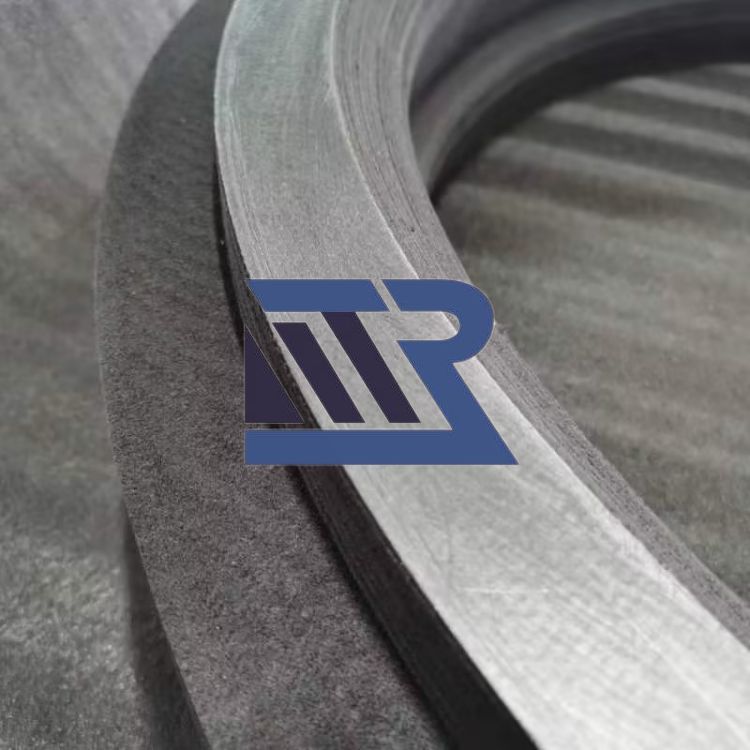

Carbon fiber hard felt is a composite material with excellent properties, including high strength, low density, and excellent wear resistance. It is widely used in fields such as aerospace, automobiles, and sports equipment. The production process of carbon fiber hard felt includes the pre-treatment of fiber materials, fiber forming, and curing processes. The following are the detailed steps for the production process of carbon fiber hard felt: 1. Selection and pretreatment of fiber materials: Firstly, choose suitable carbon fiber materials, usually high-strength and high modulus carbon fiber bundles. Then, pre-treatment is carried out on the carbon fiber, including removing impurities, removing surface coatings, and performing surface activation treatment. These steps can improve the bonding strength between fibers and the matrix. 2. Fiber forming: The formation of fibers involves stacking them together according to certain rules and methods to form a felt like structure. Common forming methods include manual stacking and automatic stacking. Manual stacking refers to manually stacking fibers one by one, while automatic stacking is accomplished using robotic arms or other devices.

3. Fiber curing: After the molding is completed, the fibers need to be cured to improve their strength and hardness. Curing is usually carried out using heat curing or heat curing resins. Thermal curing is the process of placing carbon fiber felt at high temperatures and curing the resin through a thermal reaction. Heat cured resins usually require a longer curing time to ensure complete curing of the resin. 4. Cutting and trimming: After curing, cut and trim the carbon fiber hard felt to meet the required size and shape. Cutting is usually done using mechanical cutting tools or laser cutting, while trimming involves neatly cutting the edges. 5. Surface treatment: Finally, surface treatment of carbon fiber hard felt is carried out to improve its appearance and performance. Surface treatment can include steps such as grinding, spraying varnish or coating to enhance its wear resistance, oxidation resistance, and waterproof properties.

3. Fiber curing: After the molding is completed, the fibers need to be cured to improve their strength and hardness. Curing is usually carried out using heat curing or heat curing resins. Thermal curing is the process of placing carbon fiber felt at high temperatures and curing the resin through a thermal reaction. Heat cured resins usually require a longer curing time to ensure complete curing of the resin. 4. Cutting and trimming: After curing, cut and trim the carbon fiber hard felt to meet the required size and shape. Cutting is usually done using mechanical cutting tools or laser cutting, while trimming involves neatly cutting the edges. 5. Surface treatment: Finally, surface treatment of carbon fiber hard felt is carried out to improve its appearance and performance. Surface treatment can include steps such as grinding, spraying varnish or coating to enhance its wear resistance, oxidation resistance, and waterproof properties. The above are the main steps in the production process of carbon fiber hard felt. The production of carbon fiber hard felt requires strict control and operation to ensure that the quality and performance of the final product meet the requirements. With the continuous development of technology, the production process of carbon fiber hard felt is also constantly improving and innovating to meet the needs of different fields.

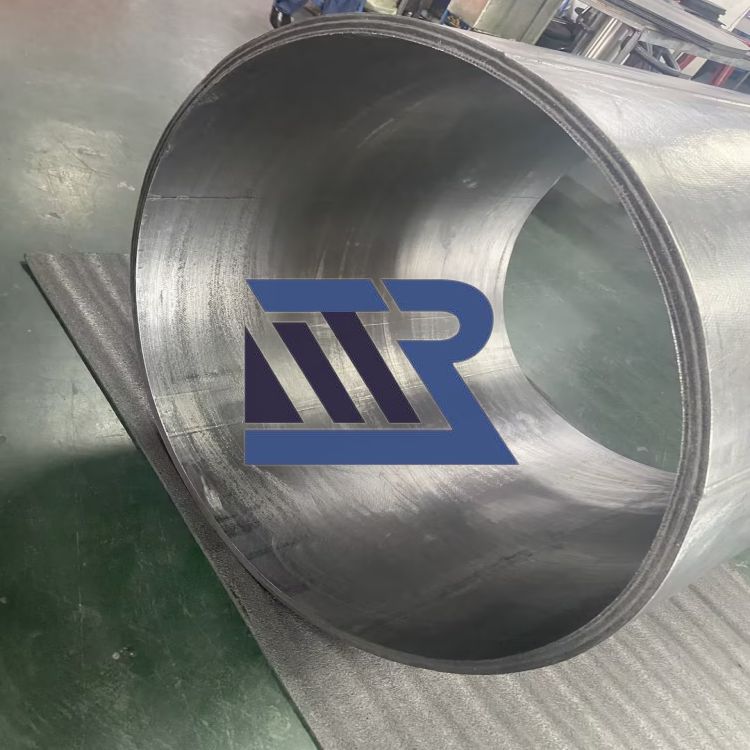

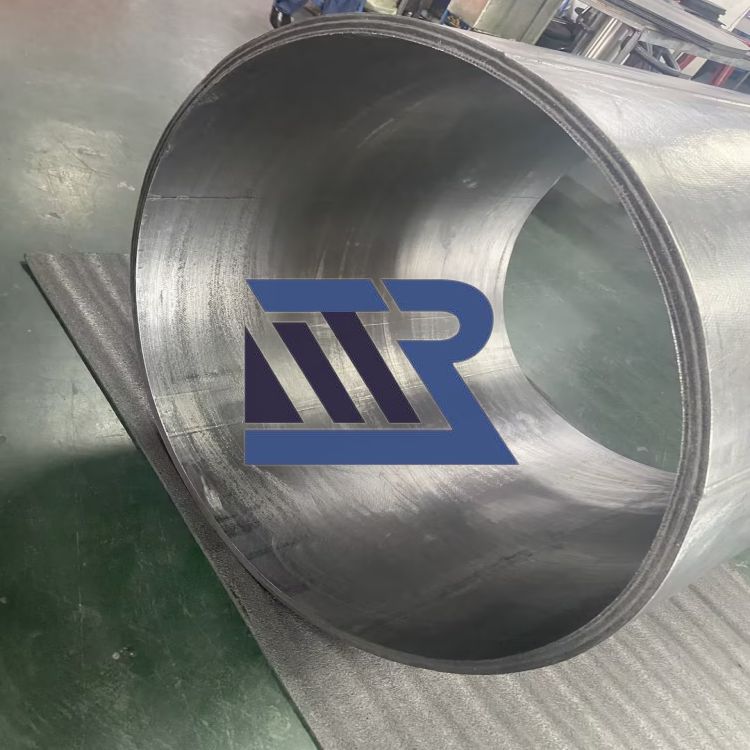

Related recommendations:Carbon Fiber Rigid Felt Tube.Vacuum Furnace Insulation Tube.Carbon Fiber Insulation Material.Vacuum Furnace Insulation Screen