From the production process of carbon fiber, it can be seen that carbon fiber is a structure similar to graphite crystals formed after high-temperature carbonization at 2000-3000 ℃ and graphitization treatment. This structure itself has high corrosion resistance in some chemical media, and its strength and modulus remain basically unchanged. However, in practical applications, carbon fibers are usually fused with matrix materials such as resins to form carbon fiber composite materials. Therefore, the corrosion resistance of carbon fiber products may differ from that of carbon fibers themselves. Carbon fiber products produced from the same material at different environmental temperatures exhibit poor corrosion resistance due to the combined effects of ultraviolet, oxygen, and humidity on the aging effect of epoxy resin composites, which is much stronger than unilateral effects. The aging of carbon fiber products generally starts from the surface and gradually develops towards its interior. With the development of application technology for carbon fiber composite products, the excellent corrosion resistance of carbon fiber composite materials has won more and more application opportunities in many harsh working scenarios.

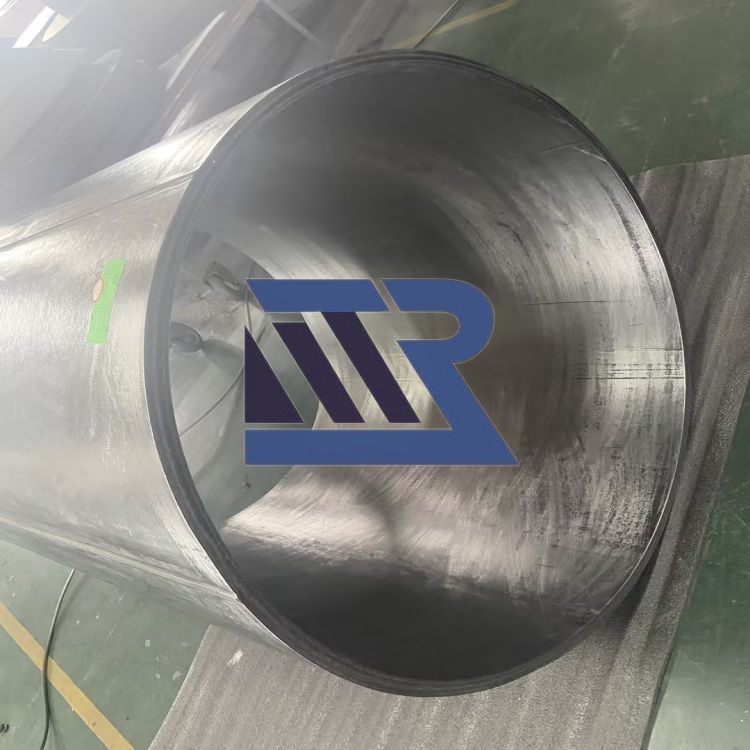

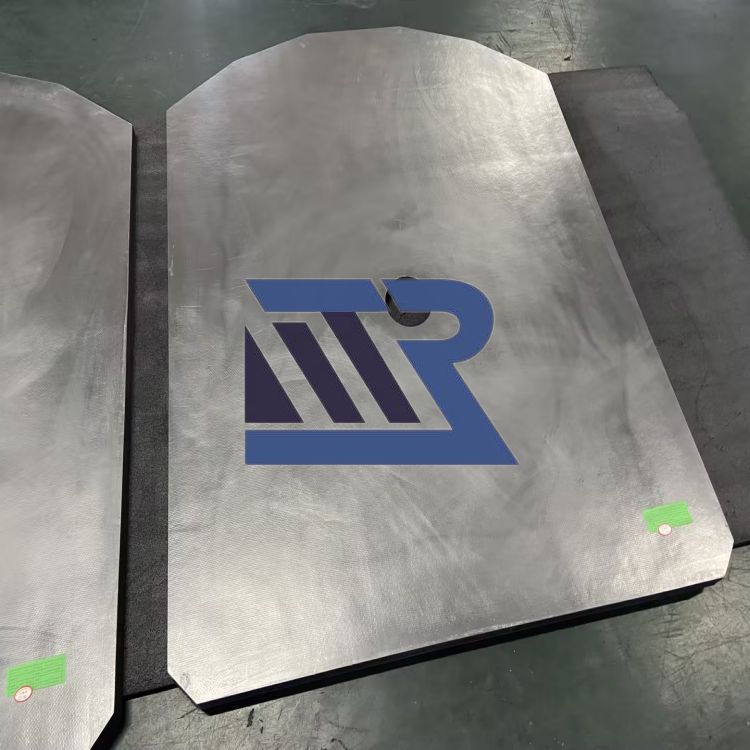

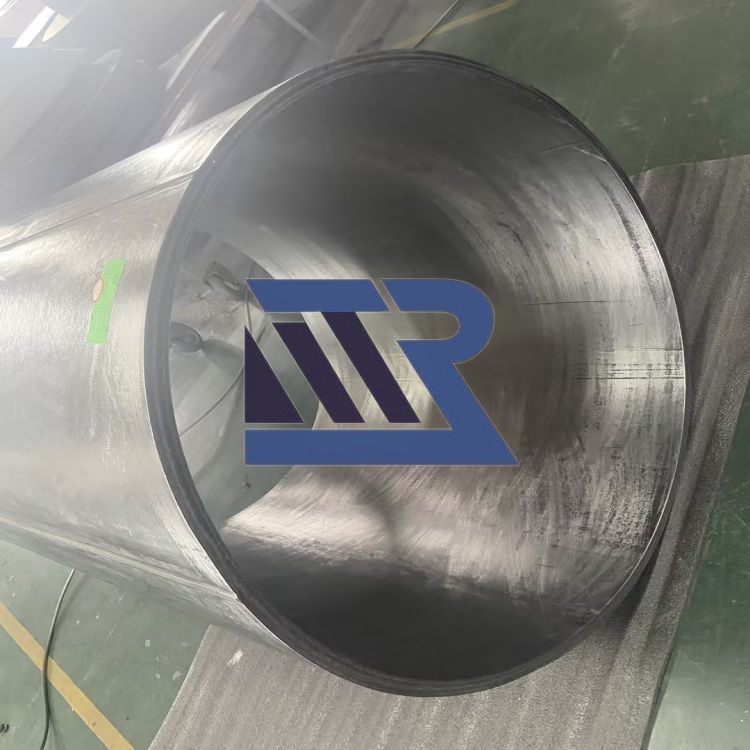

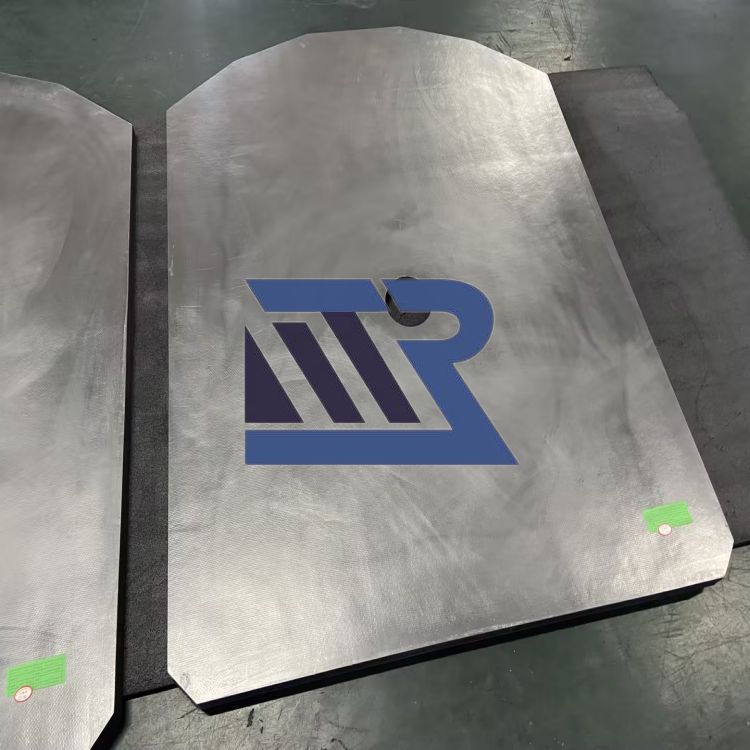

Hunan Meite Rui New Material Technology Co., Ltd. is a production factory for high-temperature furnace thermal insulation materials! Our company adheres to the corporate philosophy of being dedicated, focused, and professional, and is committed to the continuous research and application of thermal insulation material technology in thermal fields. The company's main products include graphite hard felt, reinforced composite hard felt, multi type composite hard felt (special-shaped overall production), graphite felt, high-temperature carbon felt and other thermal insulation materials. The hard felt series has the advantages of rigidity, self-supporting, high strength, no short fiber detachment, low thermal conductivity, etc. that traditional insulation materials do not have. It is more energy-saving, environmentally friendly, easy to disassemble, easy to maintain, and can extend the service life of high-temperature furnaces. The product is suitable for various high-temperature vacuum furnace equipment (such as single crystal growth furnace, polycrystalline casting furnace, polycrystalline reduction furnace, polycrystalline ingot furnace, vacuum sintering furnace, hot pressing furnace, heat balance furnace, electromagnetic induction furnace, medium and high frequency induction furnace, non oxidizing atmosphere high-temperature equipment, high-purity silicon hydrogenation furnace, etc.), and is widely used in fields such as solar energy, vacuum metallurgy, chemical new materials, atomic energy, semiconductor, electronic new energy, etc.

Hunan Meite Rui New Material Technology Co., Ltd. is a production factory for high-temperature furnace thermal insulation materials! Our company adheres to the corporate philosophy of being dedicated, focused, and professional, and is committed to the continuous research and application of thermal insulation material technology in thermal fields. The company's main products include graphite hard felt, reinforced composite hard felt, multi type composite hard felt (special-shaped overall production), graphite felt, high-temperature carbon felt and other thermal insulation materials. The hard felt series has the advantages of rigidity, self-supporting, high strength, no short fiber detachment, low thermal conductivity, etc. that traditional insulation materials do not have. It is more energy-saving, environmentally friendly, easy to disassemble, easy to maintain, and can extend the service life of high-temperature furnaces. The product is suitable for various high-temperature vacuum furnace equipment (such as single crystal growth furnace, polycrystalline casting furnace, polycrystalline reduction furnace, polycrystalline ingot furnace, vacuum sintering furnace, hot pressing furnace, heat balance furnace, electromagnetic induction furnace, medium and high frequency induction furnace, non oxidizing atmosphere high-temperature equipment, high-purity silicon hydrogenation furnace, etc.), and is widely used in fields such as solar energy, vacuum metallurgy, chemical new materials, atomic energy, semiconductor, electronic new energy, etc. Customized with pictures, we can produce various non-standard geometric shapes such as flat plates, discs, cones (discs), and cylinders! Can provide hot chamber total installation services. Communication hotline: 18975351523 Customer service QQ: 1805735158 Technical service hotline: 0731-22575898

Related recommendations:Carbon Fiber Insulation Materia.Carbon Fiber Insulation And Heat Insulating Board.Vacuum Furnace Insulation Material.Carbon Fiber Thermal Insulation Material

Hunan Meite Rui New Material Technology Co., Ltd. is a production factory for high-temperature furnace thermal insulation materials! Our company adheres to the corporate philosophy of being dedicated, focused, and professional, and is committed to the continuous research and application of thermal insulation material technology in thermal fields.

Hunan Meite Rui New Material Technology Co., Ltd. is a production factory for high-temperature furnace thermal insulation materials! Our company adheres to the corporate philosophy of being dedicated, focused, and professional, and is committed to the continuous research and application of thermal insulation material technology in thermal fields.